MH Electric Hoist Single Beam Gantry Crane – Industrial Material Handling Solution

Overview of MH Series Light-Duty Overhead Lifting Equipment

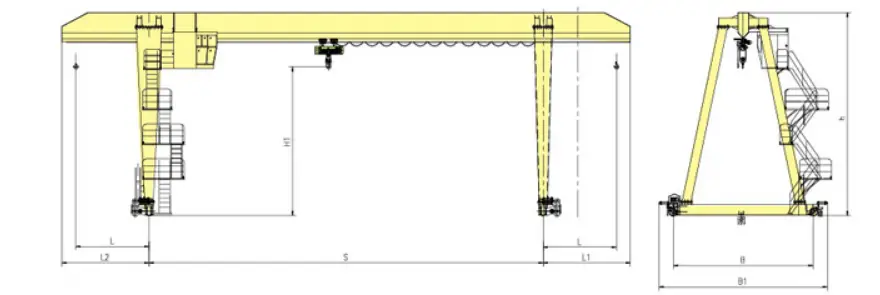

The MH series electric hoist gantry crane represents a versatile material handling solution designed for efficient industrial operations. This single beam overhead crane system offers lifting capacities ranging from 1 to 20 tons, making it ideal for light to medium-duty applications in various industries. With working classifications of A3 or A4, this rail-mounted lifting equipment provides reliable performance for warehouses, manufacturing facilities, and outdoor storage yards.

Engineered with CD or MD wire rope electric hoists, this mid-light duty gantry lifting system combines durability with operational efficiency.

Key Components of the Single Beam Material Handling Crane

This industrial overhead crane integrates several critical components for optimal performance:

- Main beam structure: High-strength single girder design for reliable load support

- Support leg assembly: Robust vertical supports ensuring stability during lifting operations

- Bottom end beam: Structural foundation providing crane stability

- Lifting mechanism: Precision electric hoist for smooth vertical movement

- Travelling system: Rail-mounted mobility for horizontal positioning

- Electrical controls: Advanced control systems for safe, efficient operation

Technical Specifications for Electric Hoist Overhead Cranes

Performance Parameters of the MH Light-Duty Lifting System

| Capacity | 3t | 5t | 10t | 16t | 20t |

|---|---|---|---|---|---|

| Lifting Height | 6-12m | 6-12m | 6-12m | 6-12m | 6-12m |

| Hoisting Speed | 8 (8/0.8) m/min | 8 (8/0.8) m/min | 7 (7/0.7) m/min | 3.5 (3.5/0.35) m/min | 3.5 (3.5/0.35) m/min |

| Trolley Travel Speed | 20 m/min | 20 m/min | 20 m/min | 20 m/min | 20 m/min |

| Crane Travel Speed | 20 m/min | 20 m/min | 20 m/min | 20 m/min | 20 m/min |

| Work Classification | A3-A4 | A3-A4 | A3-A4 | A3-A4 | A3-A4 |

| Track Configuration | P24/P38 | P24/P38 | P38/P43 | P38/P43 | P38/P43 |

Classification of Single Beam Overhead Lifting Equipment

Box Type Single Girder Material Handling Crane

The box-type gantry lifting system features a robust construction utilizing premium steel plates, C-steel, and I-steel components. This configuration employs standard CD or MD electric hoists that traverse along the lower flange of the main I-beam structure. The warehouse gantry crane with box beam design offers exceptional structural integrity, making it suitable for indoor and outdoor material handling applications requiring consistent performance and reliability.

Key Features of Box-Type Configuration

- Enhanced load distribution through welded steel plate construction

- Optimized for 5-ton to 20-ton lifting capacity requirements

- Ideal for facilities with moderate wind exposure

- Superior rigidity for precision material positioning

Truss Type Lightweight Gantry Lifting System

The truss-style single beam crane represents an innovative approach to overhead lifting, constructed primarily from steel bars rather than plates. This lightweight material handling equipment offers significant advantages for specific applications, particularly in environments requiring enhanced wind resistance and reduced structural weight.

Distinctive Advantages of Truss-Type Construction

- Substantially lighter than comparable box-type designs

- Superior wind resistance for outdoor gantry crane installations

- Cost-effective solution for long-span material handling applications

- Reduced foundation requirements due to lighter overall weight

- Optimal for port and shipyard lifting operations

Industrial Applications for CE ISO Certified MH Series Overhead Cranes

Primary Usage Environments

Our CE ISO certified lifting equipment is approved for use in:

- Manufacturing facilities: Assembly lines and production areas requiring 3-ton to 10-ton CE compliant lifting solutions

- European Union warehouses: Inventory management with CE marked heavy load material handling equipment

- International port terminals: Container handling meeting IMO and ISO standards for cargo operations

- Granite and stone industry: Moving heavy stone blocks with CE certified precision lifting equipment

- Cement and construction: Pipeline installation with ISO approved material transport systems

- Open storage yards: Outdoor inventory management with weather-resistant CE certified gantry systems

- Shipbuilding facilities: Component assembly meeting maritime certification requirements

- Container terminals: Efficient cargo handling with internationally certified storage equipment

- Export markets: Full compliance for global deployment with CE ISO documentation

Safety Restrictions

The equipment is specifically designed for general material handling and must not be used for:

- Molten metal transportation

- Flammable material handling

- Explosive substance movement

- Applications exceeding specified load ratings

Advantages of Electric Hoist Single Beam Lifting Solutions

Operational Benefits

- Simplified structure: Streamlined design enables quick installation and commissioning

- High efficiency: Optimized performance for industrial material handling productivity

- Low maintenance requirements: Reduced operational costs through reliable components

- Standardized components: Interchangeable parts ensure easy servicing and replacement

- Versatile configurations: Customizable for specific warehouse and factory crane needs

Economic Advantages

- Lower initial investment compared to double girder alternatives

- Reduced power consumption through efficient motor systems

- Minimal foundation requirements for light to medium duty applications

- Extended service life with proper maintenance protocols

Comprehensive Safety Features for Industrial Lifting Operations

Modern electric hoist overhead cranes incorporate multiple safety systems:

Primary Safety Systems

- Overload protection device: Automatic warning system preventing dangerous overloading conditions

- Limit switches: Precision controls preventing over-travel in lifting and lowering operations

- High-quality buffers: Polyurethane impact absorbers ensuring smooth stops and extended equipment life

- Dual control options: Cabin control and remote control gantry crane operation for operator safety

- Voltage protection: Low voltage safeguards protecting against electrical fluctuations

Emergency Safety Features

- Emergency stop system: Instant braking capability for critical situations

- Current overload protection: Electrical safety preventing motor damage

- Anti-sway technology: Stabilization systems for precision material positioning

- Load monitoring: Real-time weight verification for safe lifting operations

- Weather protection options: Enclosed electrical components for outdoor crane installations

Selecting the Right Single Beam Material Handling Solution

When choosing a gantry crane for warehouse or industrial use, consider these factors:

Capacity Requirements

- Evaluate maximum load weights for your 5-ton, 10-ton, or 20-ton lifting needs

- Consider future expansion requirements

- Account for dynamic loading conditions

Environmental Factors

- Indoor versus outdoor installation requirements

- Wind exposure for truss type outdoor gantry systems

- Temperature and humidity considerations

- Corrosion resistance needs for coastal or chemical environments

Operational Considerations

- Frequency of use determining duty cycle selection (A3 or A4)

- Span requirements for your facility layout

- Lifting height needs for vertical material movement

- Travel distance for horizontal positioning requirements

Maintenance Best Practices for Long-Term Performance

Ensuring optimal performance of your industrial overhead lifting equipment requires:

Regular Inspection Schedule

- Regular inspection of wire ropes and electrical components

- Lubrication schedules for moving parts

- Load testing verification at specified intervals

- Electrical system checks for control reliability

- Structural inspection for box type and truss type crane configurations

- Documentation of all maintenance activities for compliance

Preventive Maintenance Actions

- Monthly visual inspections of critical components

- Quarterly lubrication of bearings and gears

- Semi-annual electrical system diagnostics

- Annual structural integrity assessments

- Replacement of wear parts per manufacturer guidelines

Versatile Material Handling for Modern Industry

The MH series represents a proven solution for facilities requiring reliable single girder lifting systems. Whether selecting a box-type crane for indoor warehouse operations or a truss-style system for outdoor port applications, these machines deliver consistent performance with appropriate safety features. From small 3-ton workshop cranes to heavy-duty 20-ton industrial systems, the MH series adapts to diverse material handling challenges while maintaining operational efficiency and safety standards.

For operations seeking cost-effective rail-mounted overhead crane solutions with proven reliability, the MH series offers the flexibility, safety, and performance required in today’s demanding industrial environments. Contact our specialists to determine the optimal