Hand Chain Hoist: Cost-Effective Manual Lifting Solution for Global Markets

The hand chain hoist, also known as a manual chain block, is a highly economical and versatile manual hand chain hoist designed for industrial lifting tasks worldwide. With a lifting capacity of 0.5 to 100 tons, this CE and ISO-certified equipment ensures safe, durable performance in factories, warehouses, ports, and power-free environments. Featuring stainless steel chains, bronze hooks, and spark-resistant wheels, this hand-operated hoist excels in flame-resistant settings, offering cost-effective and reliable solutions for diverse material handling needs.

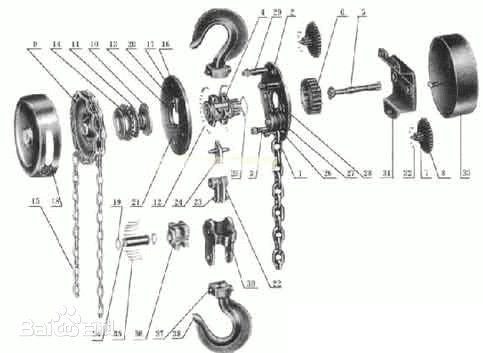

Manual chain hoist/manual chain block structure

Technical Specifications of Manual Chain Hoists

Engineered for efficiency and adaptability, the manual chain block offers the following specifications:

-

Product Type: Manual Chain Hoist

-

Lifting Capacity: 0.5 to 100 tons

-

Lifting Height: 0.5 to 3.5 meters

-

Operating Temperature: -20°C to 40°C

-

Duty Classification: Suitable for intermittent use

These specifications ensure the hand-operated hoist meets diverse industrial lifting needs while maintaining consistent performance across various environments.

Applications of Manual Chain Blocks

Manual chain blocks are widely used for short-distance material handling and equipment installation in global markets. Key applications include:

-

Industrial Environments: Factories, mining operations, construction sites, ports, shipyards, and warehouses utilize hand chain hoists for lifting and positioning heavy loads.

-

Power-Free Operations: Ideal for outdoor settings or areas with limited electricity, offering unmatched flexibility for remote or off-grid locations.

-

Specialized Applications: Compatible with monorail systems, manual single girder overhead cranes, or suspension cranes, supporting tasks such as vehicle lifting and transportation.

This versatility makes the manual chain block a preferred choice for industries seeking reliable, power-independent lifting solutions worldwide.

Advantages of Manual Chain Hoists

The hand chain hoist delivers multiple benefits, making it a top choice for global industrial lifting:

-

Safety and Durability: Compliant with CE and ISO standards, ensuring safe and long-lasting performance.

-

Compact and Portable: Lightweight and small in size, enhancing ease of handling and transport.

-

Robust Components: High-strength parts designed to manage demanding tasks with minimal effort.

-

Power-Free Operation: Enables uninterrupted lifting in areas without electrical access.

-

Cost-Effective Solution: Simple design reduces maintenance costs and ensures long-term reliability.

These advantages position the hand-operated hoist as an efficient and economical tool for global material handling needs.

Key Features of Manual Chain Blocks

Designed with advanced features, the manual chain block ensures superior performance and safety:

-

Premium Materials: Constructed from high-quality alloy steel for enhanced durability.

-

High-Strength Lifting Chain: Features an 800 MPa chain made from 20M2 material, treated with intermediate frequency quenching for low wear and corrosion resistance.

-

Reinforced Hook Design: Alloy steel hooks with a gesture-type configuration for secure load handling.

-

Controlled Lifting: Slow lifting capability prevents overloading, improving safety.

-

Global Safety Standards: Certified to meet CE and ISO requirements for international compliance.

-

Enhanced Safety Features: Includes ratchet brakes for reliable load control.

These features ensure consistent performance in demanding industrial environments worldwide.

Working Mechanism of Manual Chain Hoists

The manual chain block operates through a straightforward yet effective mechanism:

-

Lifting Process: Pulling the chain clockwise rotates the sprocket, engaging the ratchet wheel and brake base. This drives the gear system (long axis, short axis, and spline hole gear), lifting the load steadily via the chain.

-

Lowering Process: Pulling the chain counterclockwise disengages the brake base from the brake pad, stopping the ratchet wheel under the ratchet pawl’s action. The load is lowered smoothly as gears rotate in reverse.

-

Braking System: A ratchet friction chip one-way brake ensures secure load holding, with the ratchet pawl engaging the ratchet wheel under spring action for safe operation under load.

This mechanism guarantees precise and safe load handling, even in challenging global conditions.

Optimized Structure for Global Industrial Use

The hand chain hoist’s structure is designed for efficiency, durability, and global applicability:

-

Durable Components: Crafted from high-quality alloy steel for long-lasting performance.

-

High-Strength Chain: Engineered for minimal wear and corrosion resistance, ensuring reliable lifting.

-

Ergonomic Design: Lightweight and compact for easy handling and installation.

-

Safety Mechanisms: Ratchet brake and load-limiting features enhance operational safety.

-

Global Compliance: Certified to meet CE and ISO standards, suitable for international markets.

This optimized structure makes the manual chain block a robust and versatile tool for industrial material handling worldwide, delivering consistent performance with minimal maintenance.

Contact Us for Customized Solutions

If you have specific lifting requirements, our team can provide customized manual chain block solutions tailored to your needs. Contact us today to discuss your project and explore how our CE and ISO-certified equipment can enhance your operations. Reach out via our website or email for expert guidance and support.