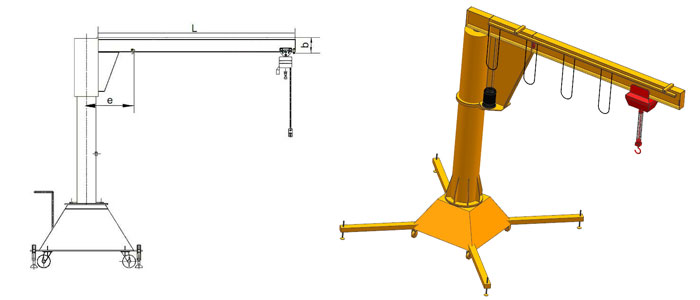

Mobile Jib Crane – Versatile and Efficient Lifting Solution

The Mobile Jib Crane, also known as a portable slewing jib crane or mobile cantilever crane, is a highly adaptable and lightweight material handling solution designed for dynamic industrial environments. Engineered for flexible maneuverability and wide applicability, this crane is an essential independent emergency lifting tool for high-efficiency automated production lines. Certified to CE and ISO standards, the Mobile Jib Crane delivers safe, reliable, and precise performance across factories, workshops, warehouses, and docks. Furthermore, its movable foundation with heavy-duty wheels enables seamless repositioning, making it ideal for temporary or space-constrained lifting tasks without requiring fixed installations.

Moreover, DONGQI offers customized Mobile Jib Cranes tailored to specific industrial lifting requirements, ensuring optimal functionality for diverse operational needs. For more options, explore our range of mobile jib crane solutions.

Applications of Mobile Jib Crane

The Mobile Jib Crane is a versatile solution for a wide range of industries, including:

-

Factories and Mines – Facilitates small equipment installation and heavy lifting tasks.

-

Workshops – Supports production lines, assembly lines, and mechanical processing operations.

-

Warehouses – Enables efficient handling and stacking of goods.

-

Docks – Assists with loading and unloading in confined spaces.

Its portable design and 360° rotation capability make it ideal for both indoor and outdoor industrial lifting applications, particularly in dynamic or temporary setups.

Advantages of Mobile Jib Crane

This crane offers several key benefits, including:

-

Flexible Maneuverability – Movable foundation with wheels allows easy positioning in any desired location.

-

360° Rotation – Jib arm rotates fully for unrestricted access to lifting areas.

-

Space-Saving Design – Compact structure maximizes workspace efficiency.

-

Cost-Effective – Eliminates the need for costly fixed installations, reducing setup costs.

-

Easy Operation – User-friendly controls enable single-operator functionality for precise material handling.

-

Low Maintenance – Durable components minimize upkeep costs and downtime, with a 1-3 year warranty for added reliability.

-

Versatile Hoist Options – Supports manual or electric chain/wire rope hoists for varied lifting needs.

To learn more, visit our advanced crane technologies for innovative solutions.

Technical Parameters of Mobile Jib Crane

|

Parameter |

Specification |

|---|---|

|

Rated Load |

0.08t, 0.125t, 0.25t, 0.5t, 1t |

|

Lifting Height |

1.5m, 2m, 3m |

|

Turning Radius |

2m, 3m |

|

Rotation Angle |

360° |

|

Rotary Way |

Electric or Manual |

|

Lifting Speed |

8m/min or 8/0.8m/min |

|

Duty Cycle |

A3 |

|

Power Supply |

3-phase 380V/50Hz (customizable for electric hoists) |

|

Ambient Temperature |

-20℃ to 40℃ |

Main Components

Jib Arm

-

Structure – Cantilever design with 360° rotation for maximum lifting flexibility.

-

Material – High-strength steel for durable and lightweight construction.

Movable Foundation

-

Design – Equipped with heavy-duty wheels for smooth mobility on standard floors.

-

Functionality – Enables easy repositioning without fixed tracks.

Hoisting Mechanism

-

Options – Electric chain hoist, electric wire rope hoist, or manual hoist for precision lifting.

-

Customization – Adjustable for specific load and speed requirements.

Electrical System (for Electric Hoists)

-

Components – Schneider electrics from France for reliable performance.

-

Protection – Includes voltage and current protection for safe operation.

Safety Features

The Mobile Jib Crane is equipped with advanced safety systems to ensure secure operations. Specifically, these include:

-

Overload Protection – Prevents unsafe load conditions.

-

Limit Switches – Ensures precise control of lifting and lowering operations.

-

Emergency Stop – Allows immediate shutdown in critical situations.

-

Anti-Sway Technology – Stabilizes loads for accurate positioning.

-

High-Quality Bearings – Enhances smooth rotation and reduces wear.

Customization Options

The Mobile Jib Crane can be tailored to meet specific industry needs, including:

-

Capacity and Dimensions – Adjustable rated loads (0.08-1t), lifting heights (1.5-3m), and turning radii (2-3m).

-

Hoist Selection – Manual hoists for precision or electric hoists for high-frequency tasks.

-

Environmental Adaptations – Weather-resistant coatings for outdoor use or corrosive environments.

-

Control Systems – Manual, electric, or wireless remote control for enhanced operational flexibility.

Maintenance Best Practices

-

Bi-Annual Lubrication – Lubricate rotating parts every six months to ensure smooth operation.

-

Periodic Cleaning – Remove accumulated material from the walking track surface as needed.

-

Corrosion Prevention – Apply paint annually for outdoor cranes or every two years for indoor cranes to prevent corrosion.

-

Regular Inspections – Check hoist, wheels, and structural components regularly to maintain safety and performance.

-

Prompt Repairs – Replace worn or damaged parts immediately to ensure safe operation.

Economic Benefits

-

Lower Initial Investment – More affordable than fixed jib or overhead cranes.

-

Reduced Installation Costs – No need for permanent foundations or tracks.

-

Flexible Deployment – Ideal for leased facilities or temporary production setups.

-

Long-Term Savings – Minimal maintenance, durable design, and a 1-3 year warranty reduce total cost of ownership.

Why Choose the Mobile Jib Crane?

In summary, the Mobile Jib Crane, offered by DONGQI, delivers unmatched flexibility, safety, and efficiency for modern industrial lifting needs. Compliant with CE and ISO standards, its portable design, customizable configurations, robust safety features, and 1-3 year warranty make it an ideal choice for factories, workshops, warehouses, and docks. This mobile cantilever crane ensures reliable performance, reduced costs, and enhanced operational safety for a wide range of material handling tasks.

For more information or to request a quote, contact us today.